Belgium Coticle, and how to flatten your stones.

The Belgium Coticle is still being quarried in the Ardenne region. This stone is a fine honing abrasive used with water. As far as I know you can now only buy the yellow stone which is cut and then glued onto the blue stone. This yellow stone occurs only in thin veins with a far greater mass of blue stone surrounding it. I have a few one piece stones from the days when they made bench stones from yellow vein still attached to the blue stone.

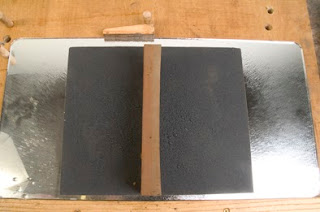

I have found that any cracking in the stone is not a problem and the stone works just fine. Notice how that I do not entirely flatten the stone in all cases. The dips you can see in stones 1 and 3 will soon ware out.

I have bought these stones in various states of disrepair, one which was used last with oil. The blue side of the stone up in its box. I thought this one as a natural slate type stone, but when flattening it fell out of its box to reveal that it was a one piece Coticle. With the oil soaked stone all I did was to flatten on wet and dry paper, this process got rid of all traces of oil.

I do like the Coticle stones, they work just like a fine waterstone, and have a great feel to them. For far more info on these stones do have a look at this

website, it will explain far more than I am willing to write up here. I have no affiliation to this company.

When first getting any stone, I always check how flat it is. All you need for this is a ruler, edge on to the length and then across the stone. If you can see any gap then the stone will need to be flattened. With natural stones this is usually very easy, All you need is some silicon carbide paper (wet and dry) and a flat surface. You will also need to check and flatten most stones at one time or another. With water stones I am always dressing the surface, with others stones it could be every year or so.

This is a very dished combination water stone. Lots of rubbing was involved, and another sheet of silicon carbide had to be used.

You will need a sheet of glass and something to spray a fine water mist. Quickly spray the glass and both sides of the silicon carbide paper. Place the paper on the glass and start rubbing all over the sheet with your stone. What grit is dependant on the hardness and dishing of your stone. I usually start with 80, 100 or 120 grits.

The Belgium stones are quick and easy to flatten. The Charnley forest was easy as well, but I used oil instead of water. Water stones are quickly dressed as well. The only stones I have had big problems with are made made oil stones, these can be very very hard and will not flatten with this technique. This does not mean that all oil stones of this type are as hard, I have come across some very soft ones, especially the cheap Chinese ones.

You may have seen the videos of the big boys getting out there 4x10inch, flat within 5 microns, diamond plates to quickly dress their waterstones. Diamond stones will flatten all natural and most made made stones with ease. The only issue I have is that they are almost £200 each. Be careful if you are using the cheaper plastic diamond plates, they are easily deformed and are often not very flat. Do check the flatness of all stones whether new or second hand

With water stones I have found the ceramic water stone flattening stone cheap and useful for dressing. I do start with silicon carbide if the stones need than just dressing.

You can use any glass plate you can find. Try and use only 3mm or thicker glass, mirror is fine to use as well. Do use the glass on a flat surface, MDF will do. Do not stick the paper down with glue onto wood or glass, it just wears out to quickly.

I have shaped lumps of natural sharpening stone with hacksaws and old rasps. These rasps are old and no longer work effectively with wood, but they are great with a softer natural stone.